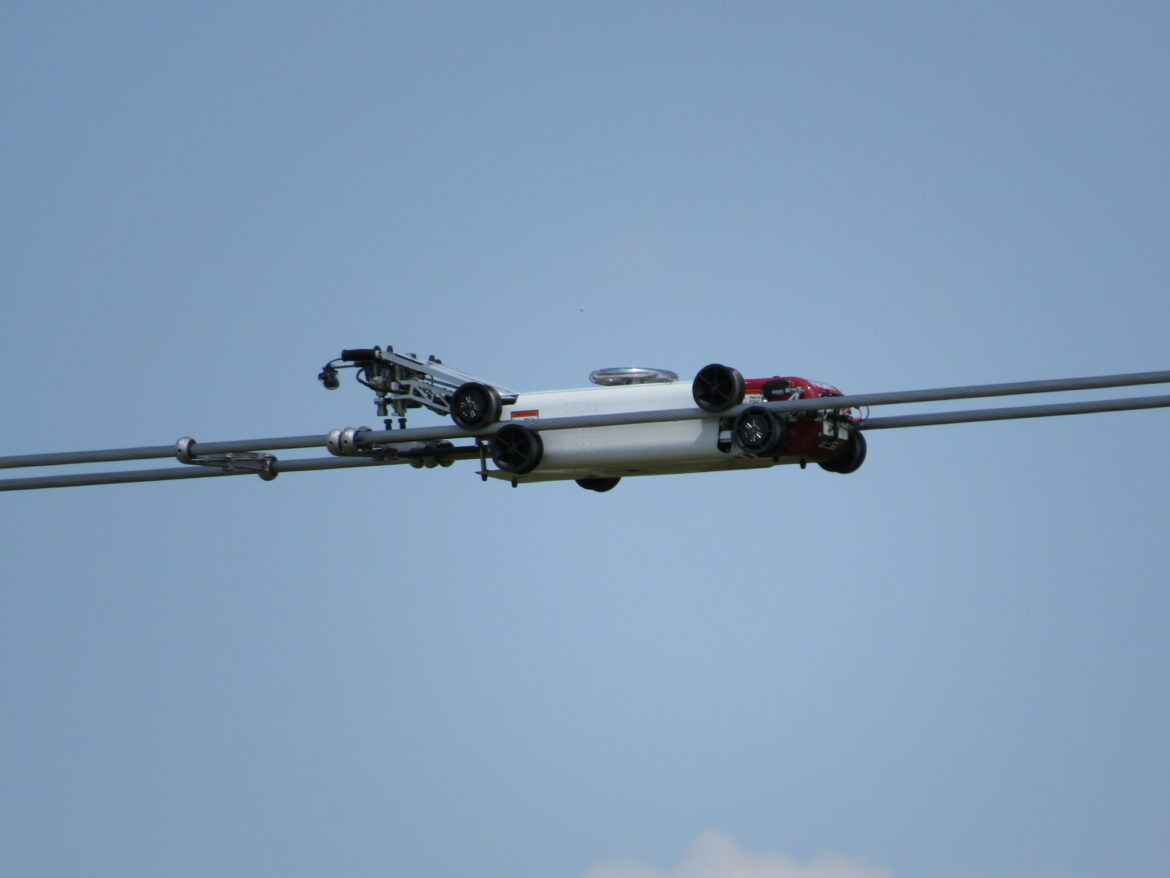

PLP and FulcrumAir have partnered to develop a robotic system for installing conductor spacers on overhead power lines. The CSR-18 robot is an unmanned system that automatically and precisely installs PLP’s CUSHION-GRIP Twin Spacers on bundled conductors, helping to reduce safety concerns for lineworkers while also exponentially increasing overall efficiency.

The CSR-18 installs PLP’s CUSHION-GRIP spacers at any pre-set distance to within a five-centimeter tolerance. The spacers are positioned at precise right angles to the conductor to ensure optimal performance, and the bolt is torqued to the utility or PLP’s exact specification. This sequence happens automatically while also logging important quality control data, such as torque values and spacer locations, enabling the utility to easily reference it for future inspection and maintenance needs.

For utilities who wish to increase productivity even more, multiple robots can be placed on the phase conductors simultaneously to rapidly install the required spacers on two adjacent spans from one initial set-up location. Once complete, the bucket truck or crane can move two structures down the line to repeat the sequence, eliminating the need for spacer carts.

Successful field testing on a 240 kV system was recently completed for industry partners and clients to showcase the safety, efficiency, and capabilities of the CSR-18™ system for power line construction projects.