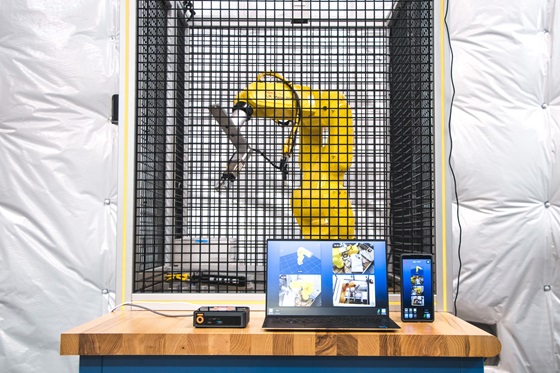

Olis Robotics is set to introduce its enhanced remote diagnostics solution for industrial automation cells at the International Manufacturing Technology Show (IMTS) 2024 in Chicago, running from September 9 to 14. This launch follows the integration of advanced Programmable Logic Controller (PLC) capabilities into the company’s existing Olis platform.

Olis Robotics’ solution offers video and telemetry-based diagnostics designed to help technicians quickly identify and resolve the causes of unplanned downtime within robotic cells, such as robot failures. By providing immediate access to critical diagnostic data, the system aims to significantly reduce downtime and allow integrators to manage more operations remotely.

The recent upgrade to Olis’ software now extends its diagnostic reach across the entire industrial cell, encompassing everything from the PLC to robotic components, including conveyors and additional hardware. With these new capabilities, users can monitor and set alerts for runtime parameters through the PLC, such as I/Os, registers, and custom tags. These features are particularly valuable for tracking Overall Equipment Effectiveness (OEE), monitoring cycle times, and detecting faults within the system.

Fredrik Ryden, CEO of Olis Robotics, emphasized the importance of the PLC in diagnosing issues, noting that the new PLC functionality enables real-time access to essential data, complementing Olis’ existing video-based diagnostics.

At IMTS 2024, attendees will be able to experience the enhanced capabilities firsthand by remotely accessing a machine tending cell located in Seattle from a tablet PC at Universal Robots’ booth. The new PLC features are currently compatible with Rockwell Automation’s Allen Bradley PLCs, and robotic arms from manufacturers such as Universal Robots, Kawasaki, and FANUC. Plans are in place to expand compatibility with additional PLCs and robotic arms in the future.

Bill Ordakowski, Sales Engineer at Olis Robotics, highlighted the significant impact of the new PLC functionality, stating that early users have reported increased confidence in their ability to monitor and debug systems. This sentiment was echoed by Steve Solack, Controls Engineering Manager at Mission Design & Automation, who noted that the enhanced access to diagnostic data reduces the time and expertise required to address issues, thereby minimizing downtime for customers.

Looking ahead, Kilen Multop, IT Director at Kaitech Automation, expressed optimism about the role of Olis in supporting the firm’s future expansion. He cited the platform’s ability to facilitate rapid deployment of robot cells and long-term performance tracking as critical to their growth strategy.

The new functionalities introduced by Olis Robotics are designed not only to decrease downtime costs associated with robot failures but also to improve overall production throughput. For example, in applications where a robot is inserting bolts into a part, the system can alert operators when supplies are low, ensuring continuous operation.

Olis Robotics anticipates that the new features will be well-received by both manufacturers and integrators at IMTS, showcasing the potential for reducing overall downtime in industrial automation systems.