Roboverse Reply, specializing in the integration of Robotics and Reality Capture with Mixed Reality, has won the Advanced Industrial Robotic Applications (AIRA) Challenge for the second consecutive year. The competition, which aims to foster innovative solutions for remote control of mobile robots during autonomous inspections in production environments, highlighted Roboverse Reply’s expertise in combining Artificial Intelligence with human capabilities to address complex industrial tasks.

The final event of the AIRA Challenge took place at ACHEMA, the world’s largest trade fair for the process industry. The competition, supported by major chemical and pharmaceutical companies such as BASF, Bayer, Boehringer Ingelheim, and Wacker, sought to advance new robotics applications within their sectors. The five finalists demonstrated the remote navigation of robots through production sites, performing tasks such as door operation, system maintenance, and inventory checks.

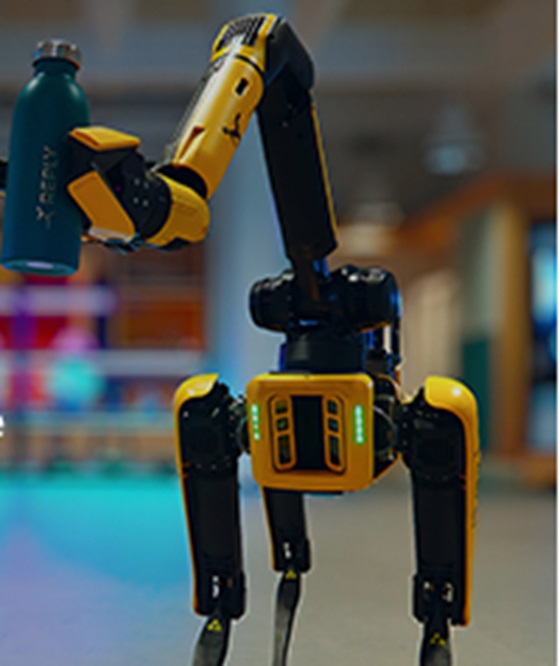

Roboverse Reply impressed the jury with its user-friendly, scalable, and enterprise-ready solution. Utilizing standard components like VR glasses, their platform allows intuitive control of mobile robots, including Boston Dynamics’ Spot, through hand tracking or controllers to maneuver gripper arms accurately. The system also provides access to additional information, such as measured values and site plans, enabling more informed decision-making. The data is processed within the customer’s cloud infrastructure, allowing remote access and seamless integration into existing systems.

Filippo Rizzante, CTO of Reply, commented on the achievement: “We are proud to have won the prestigious AIRA Challenge, affirming our expertise in developing mobile robot solutions for industrial applications. In our Robotics Lab, we continuously experiment with the latest trends in Spatial Computing and Embodied AI to tackle our clients’ challenges. Solutions like the Roboverse Reply’s Robotic Platform enable companies to manage unforeseen events flexibly and remotely, ensuring precise interventions and effectively preventing industrial plant downtime.”