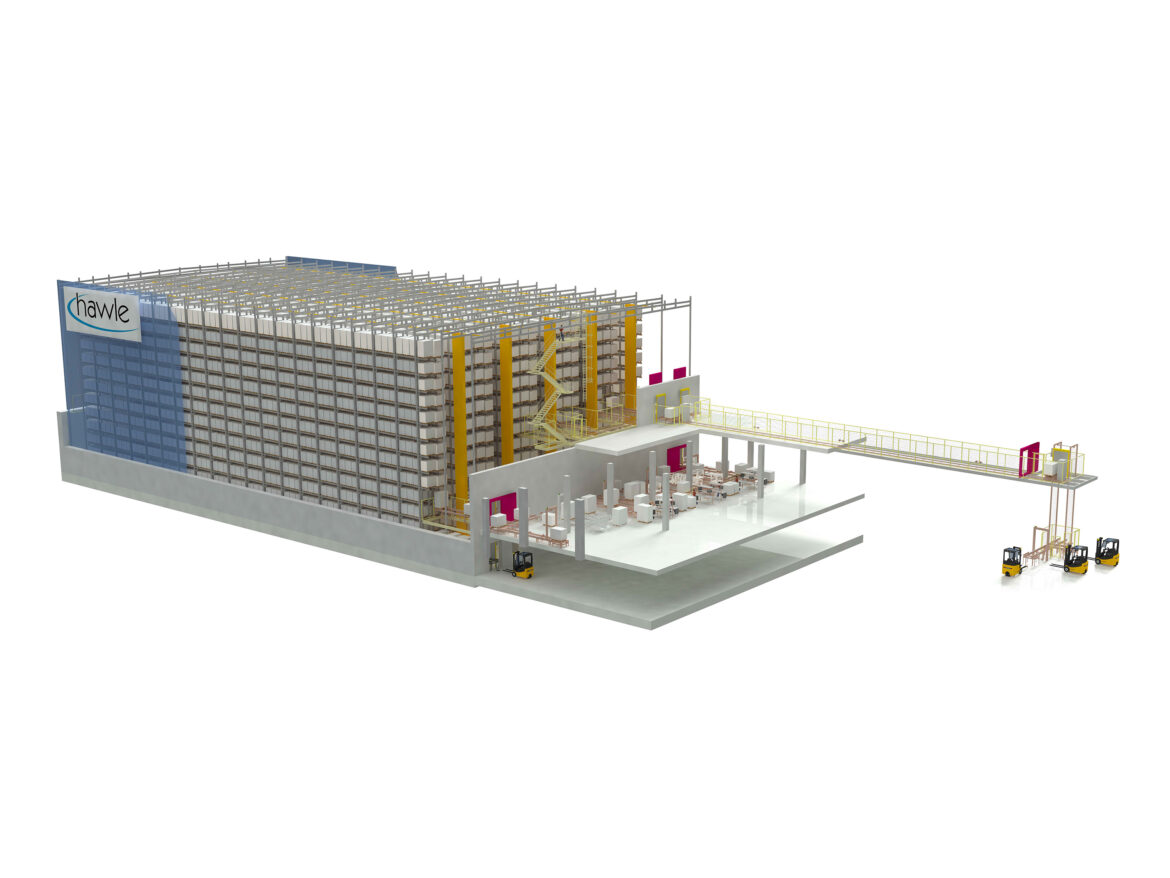

Hawle Armaturen GmbH, a manufacturer of heavy-duty valves for municipal water and sewage management, as well as gas supply, has awarded Jungheinrich with the construction of a new logistics warehouse. The company will build a fully automated high-bay warehouse with over 15,000 storage locations and five aisles near Hawle’s headquarters in Freilassing, Germany, by October 2024. The warehouse, planned as a greenfield project, will replace Hawle’s former manual distribution center.

Hans-Joachim Maier, Managing Director of project developer Maier Intraplan, explains his company’s choice of the intralogistics experts from Hamburg: “Jungheinrich convinced us with the best solution and their high level of commitment to implementing our requirements.” “The chemistry was good from the start, enabling an open and productive dialogue,” adds Thomas Bohl, Managing Director of Hawle Armaturen GmbH. “Jungheinrich impressed us as a complete supplier – from steel racking systems and warehouse cranes to control systems and WMS software,” Bohl says.

Ergonomic Order Picking

Finished goods from production will be stored in the high-bay warehouse, which is designed as a steel silo structure (72 x 35 x 25 meters). These goods will later be automatically transported to the order picking area. A bridge structure connects the conveyors with the production line. The conveyor system is connected to a manual storage area in the basement of the warehouse.

There is also space for incoming goods, raw materials, and semi-finished products. Using a conveyor system, both pallet cages and Euro pallets, as well as special pallets weighing up to 1,200 kilograms, are transported. This ensures smooth operations and guarantees the safety of the various containers. The incoming goods station and the six workstations for order picking with ergonomic lifting tables are located on the ground floor.

In addition to the steel silo structure, including roof and wall cladding, Jungheinrich’s delivery includes five warehouse cranes with PLC and visualization, as well as the complete conveyor system with six order picking workstations. An important item on Hawle Armaturen’s order list is Jungheinrich’s WMS for automated storage and material flow. Hawle was particularly impressed by the meticulous analysis of the IT processes conducted by Jungheinrich’s experts on-site.