Realtime Robotics, provider of collision-free autonomous motion planning for industrial robots, announced that it has partnered with HLS Engineering Group, a business associate in the field of integrated engineering, with expertise in the fields of manufacturing, mechanical engineering and robotic automation.

The partnership aims to bring together Realtime Robotics’ Optimization-as-a-Service solution, which uses a combination of proprietary optimization software and experienced robotics and application engineering insights to improve a manufacturer’s overall productivity, with the HLS team’s experience as a partner to industrial manufacturing customers in the automotive, aerospace and other industries.

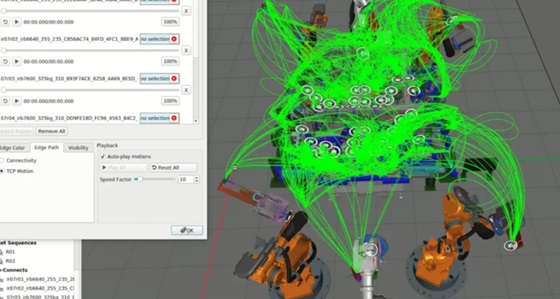

The combined solution is aid to allow manufacturers to analyze and optimize their automation cells, improving efficiency and productivity within weeks instead of several months. HLS’ scanning technology will be utilized to virtualize a customer’s cells, collecting data and creating a digital twin of their manufacturing operations.

That information will be used with Realtime’s Optimization-as-a-Service to analyze and identify any bottlenecks within production. The service generates and tests hundreds of thousands of potential robot paths, determining the best motion sequences based on target assignment, robot reach, and any other customer-desired parameters.

This process can be completed without causing any delays in ongoing production, and once the results are completed and validated, they can immediately be transferred to the production floor.