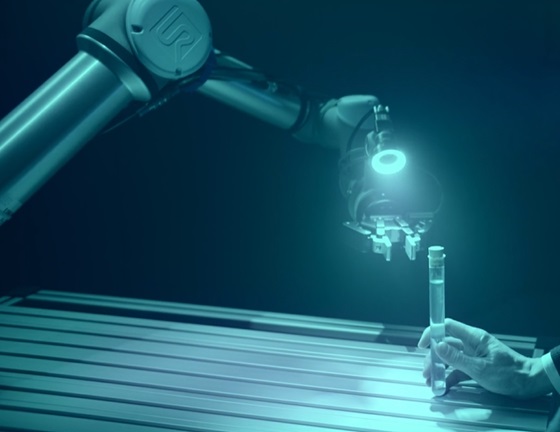

Micropsi Industries released MIRAI 2, the newest version of their AI-vision software designed for robotic automation. This software is an upgrade from the previous version, aimed at assisting manufacturers in solving a variety of automation tasks that involve differences in position, shape, color, lighting, and background.

The new features in MIRAI 2 are tailored to more effectively meet the distinct challenges faced by these industries. Micropsi Industries has also introduced specialized service teams, combining their in-house expertise with system integration partners. This initiative aims to provide comprehensive support for complex robotic systems implementing advanced AI solutions.

MIRAI, working on enabling robots to dynamically respond to varying conditions within factory environments, does not require controlled lighting, pre-defined visual features, CAD data, or extensive computer vision knowledge. This adaptability makes it a practical solution for a range of industrial applications.

The improvements in MIRAI 2 include the capability to detect unexpected workspace situations, a new automated process for gathering training data, and compatibility with high-standard industrial PCs for enhanced dependability in rough factory conditions. These upgrades simplify the training and deployment of the software. Additionally, most applications now no longer require a force-torque sensor, leading to cost reductions and more robust performance.

New in MIRAI 2 is the introduction of robot skill-sharing. This feature allows the skills trained on one robot to be quickly and easily transferred to others within a fleet. This skill-sharing enhances efficiency and consistency across multiple robots.

The functions in MIRAI 2 include the ability for users to share robot skills between different robots, which can significantly reduce the need for additional training in identical conditions. It also introduces a semi-automatic data recording system that minimizes manual workload and enhances the quality of recorded data.

The software now operates without the necessity of a force/torque sensor, lowering costs and simplifying setups. An added abnormal condition detection feature allows MIRAI to halt operations when unexpected conditions arise, facilitating human intervention or automated adjustments. Lastly, the software’s compatibility with industrial-grade hardware ensures reliable performance in challenging factory environments.