University of Washington researchers have developed “MobiPrint,” a mobile 3D printer capable of autonomously mapping indoor spaces and printing objects directly onto surfaces, such as floors. Presented at the ACM Symposium on User Interface Software and Technology , the system aims to simplify the process of integrating 3D-printed elements into physical environments.

Traditional 3D printing setups require manual measurement and object placement, while MobiPrint’s mobility eliminates this by measuring rooms with LiDAR and allowing users to design and print objects within the mapped space.

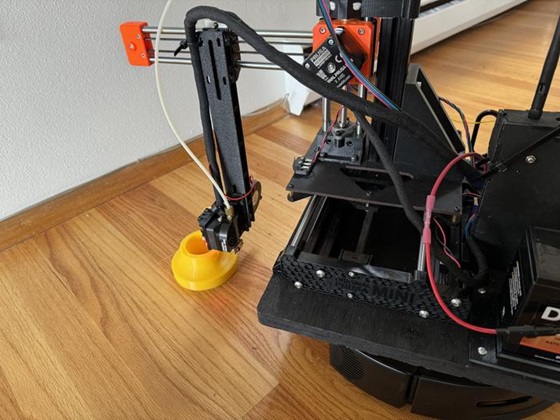

The MobiPrint prototype, built on a modified consumer vacuum robot, can print various items including accessibility features, custom home additions, or artistic elements. For example, it can create tactile markers that assist blind or low-vision individuals with navigation by providing information or warning of hazards, or build ramps to accommodate uneven flooring. The device’s current capabilities include printing objects up to three inches tall, using polylactic acid (PLA) bioplastic as the primary material. Future iterations may expand to different materials and surfaces, such as printing on walls or outdoor spaces with concrete.

The system’s design interface allows users to choose a model from MobiPrint’s library or upload their own designs. The user then selects the desired location on a digital map, adjusting the object’s scale and positioning before initiating the print process. Once configured, MobiPrint moves to the specified location and prints the object directly onto the floor.

Further development goals for the project include enabling MobiPrint to remove and recycle printed objects and expanding its use to outdoor applications. The team also envisions practical future scenarios, such as using MobiPrint to create temporary ramps on sidewalks to improve accessibility.

Photo credit: Zamora et al./UIST ‘24